Pressurized IH Rice Cooking facility SILK

Pressure IH

Environmentally friendly

IH

Environmentally friendly

next-generation rice-cooking facility

Brand concept

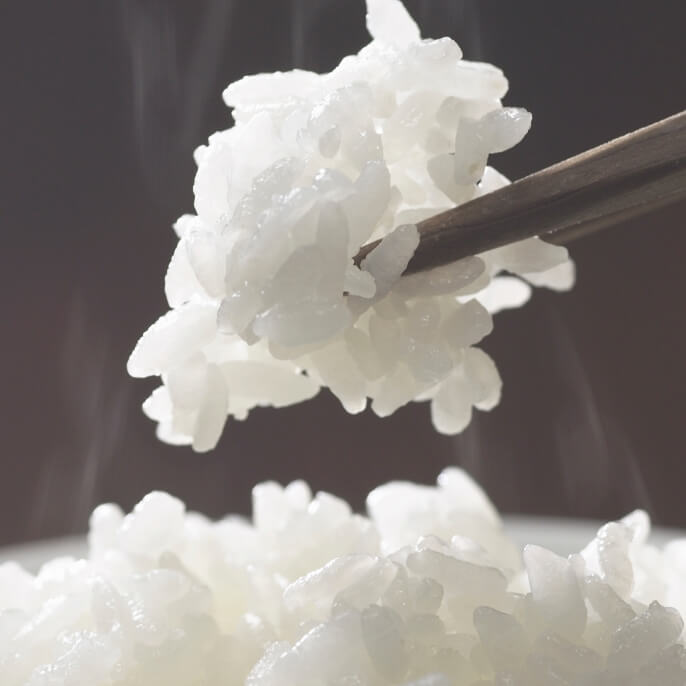

Make every grain, every bowl, delicious

We have honed our rice processing technology for more than 120 years guided by a desire to promote health through food.

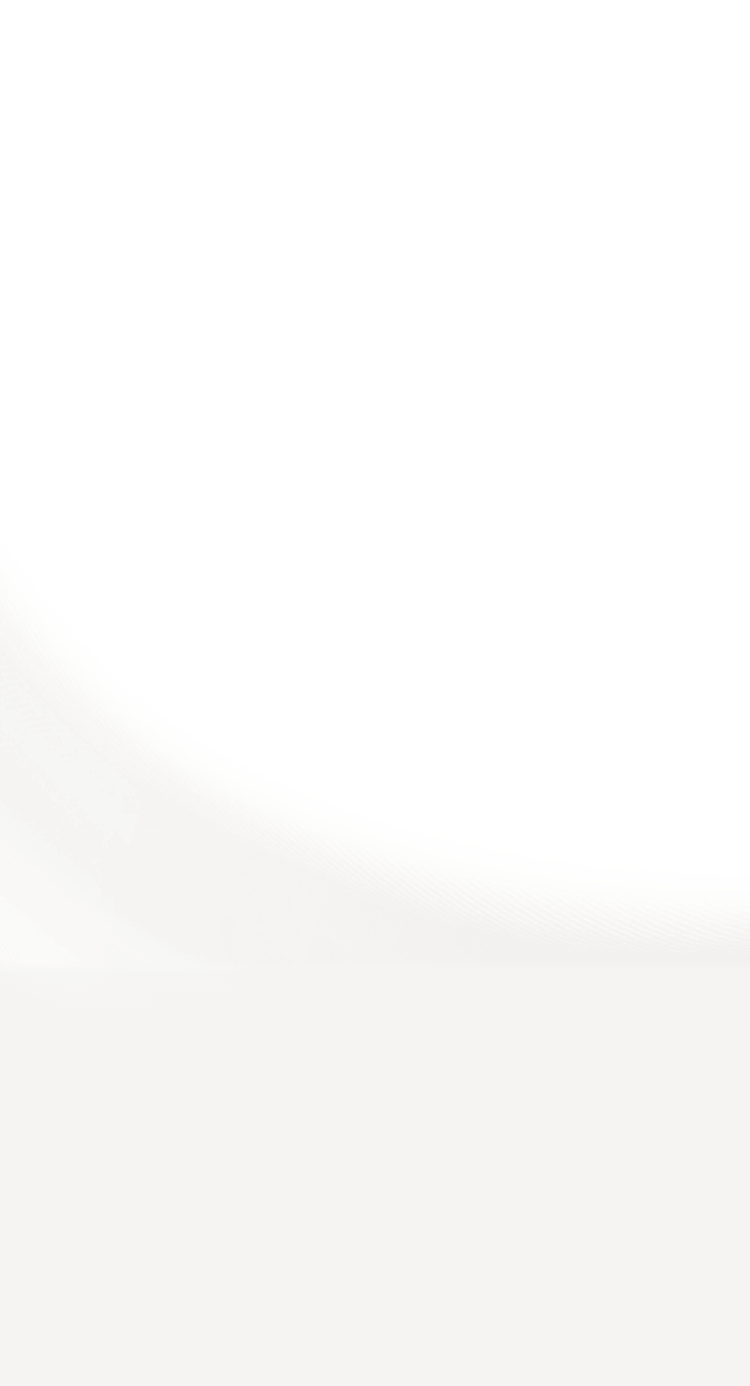

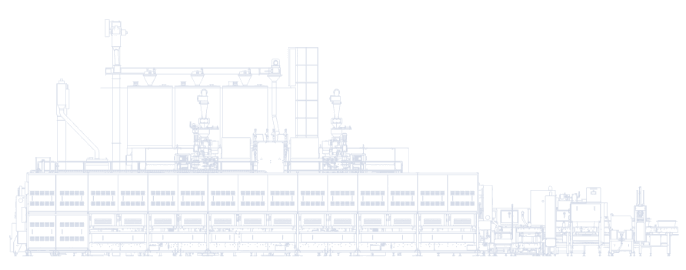

"Pressurized IH rice cooking equipment" proposed by SATAKE improves taste, stabilizes quality, and saves space.

It is designed with workers and the environment in mind and solves various problems faced by rice cooking facilities.

About "SILK"

Origin of the "SILK" brand name

S

SATAKE

I

Induction

Heating

L

Low

Emission

K

Kitchen

System

Expressed by connecting four acronyms. In addition, It is superimposed on the image of silk such as "high-grade," "high quality," and "elegant," "gentle," "smooth," and "shiny."

Brand logo's tagline "Make every grain, every bowl, delicious" is in order to achieve the distinctive features of a pressurized IH rice cooker "firm grainness", "evenly cooking," and "maintaining good taste" by cooking each grain carefully and thoroughly, we express our desire to make every rice delicious.

Product Overview What is Pressurized IH Rice Cooking facility?

In the Pressurized IH Rice Cooking facility SILK proposed by SATAKE, which has been thoroughly acquainted with rice, improved.

We aimed to design our products in consideration of people and the environment that work in the rice-cooking facility.

Advantages of SILK

Improvement of taste and quality stability

Space-saving

Rice cooking facility that is friendly to people and the environment

Introduction of

Rice Cooking process

of SILK

In the Pressurized IH Rice Cooking facility SILK proposed by SATAKE, which has been thoroughly acquainted with rice, has know-how on rice from rice washing to cooker washing.

We have built a line that maintains the original taste of rice with "Firmness" and "Gloss."

Why SATAKE is Chosen for Rice Cooking Facilities

We have honed our rice processing technology for more than 120 years since our founding, with the belief that we want to create a good healthy people through food.

We handle nearly all machines and equipment used from post-harvest drying and processing, rice milling, sorting, to producing pre-washed rice, supporting food around the world.

Case studies

#01 BEISHIN ISHIKAWA inc.

Management with Sincerity for Rice and Local Communities

In November 2022, the company introduced a “pressurized IH rice cooking line (72 kettles x 2 lines). The rice is highly evaluated as “tasty even when cold” at school lunch sites.

#02 Don Don-Rice

Awareness and pride in food infrastructure and lifelines

In December 2020, the company introduced Satake's “pressurized IH rice cooking line (120-cooker line). It has been well received not only in terms of taste, but also in terms of quality control automated by PC and working environment.

Frequently Asked

Questions

What is the difference between pressurized and non-pressurized?

- High-pressure, high-temperature rice cooking at 1.2 atmospheres (106°C) allows heat to penetrate to the core of the rice, resulting in rice that is resistant to deterioration in eating quality and is fluffy and shiny.

What is the difference between gas and IH cooking?

- Gas rice cookers only heat the bottom of the pot, while SILK cookers can heat the pot from both the bottom and sides, allowing for more precise heating adjustment.

Isn't IH a low-heat cooker?

- IH has higher thermal efficiency than gas, and can produce the same heat power as gas with fewer calories. Since the heat power is not visible, it may appear weak at first glance, but in fact, IH boasts strong heat power due to bottom and side heating, and is in no way inferior to gas.