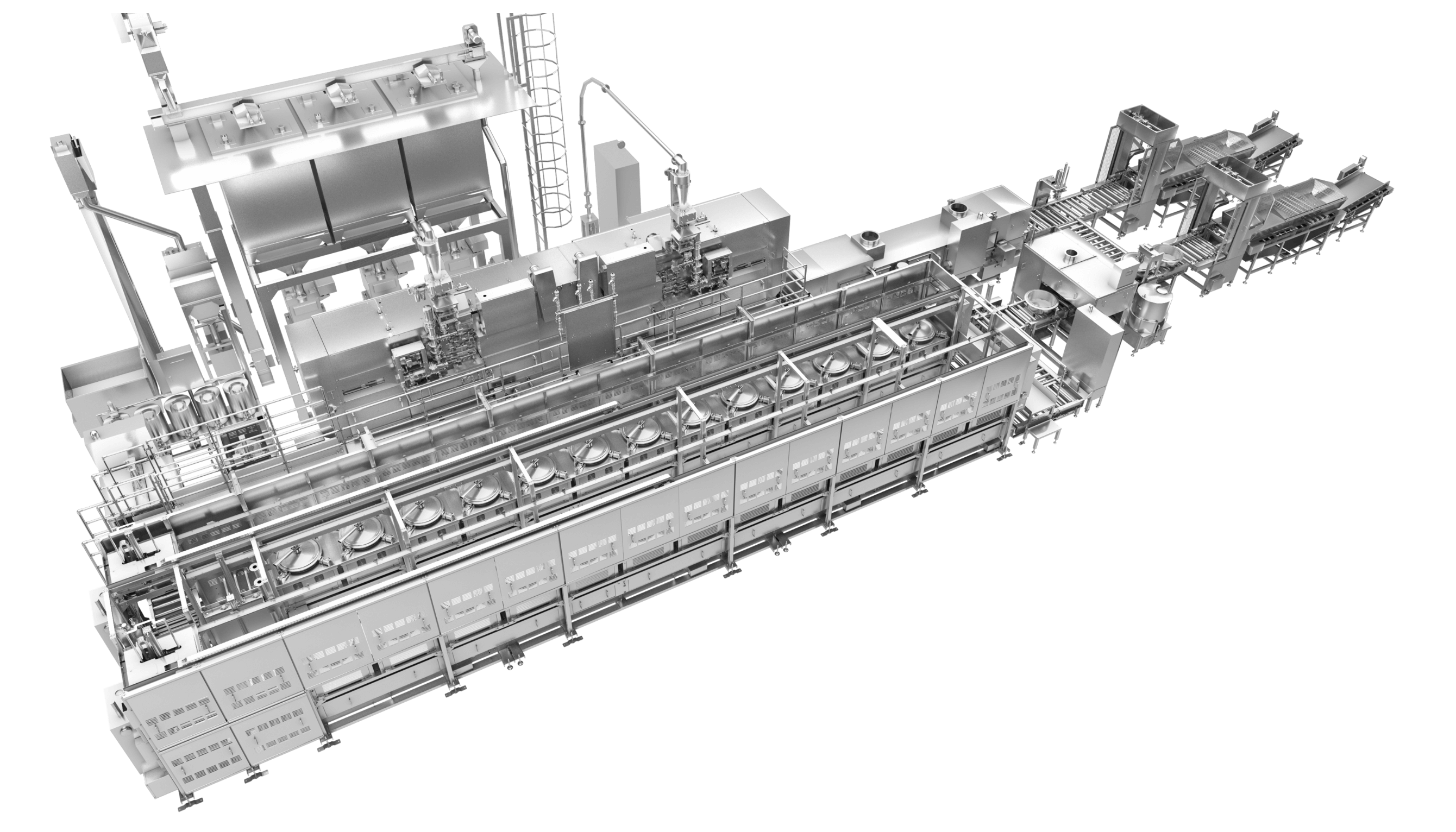

Each process of Rice Cooking facility SILK

Rice delivery process

Rice washing process

Soaking process

Seasoning process

Rice cooking process

Steaming process

Inversion process

Cleaning process

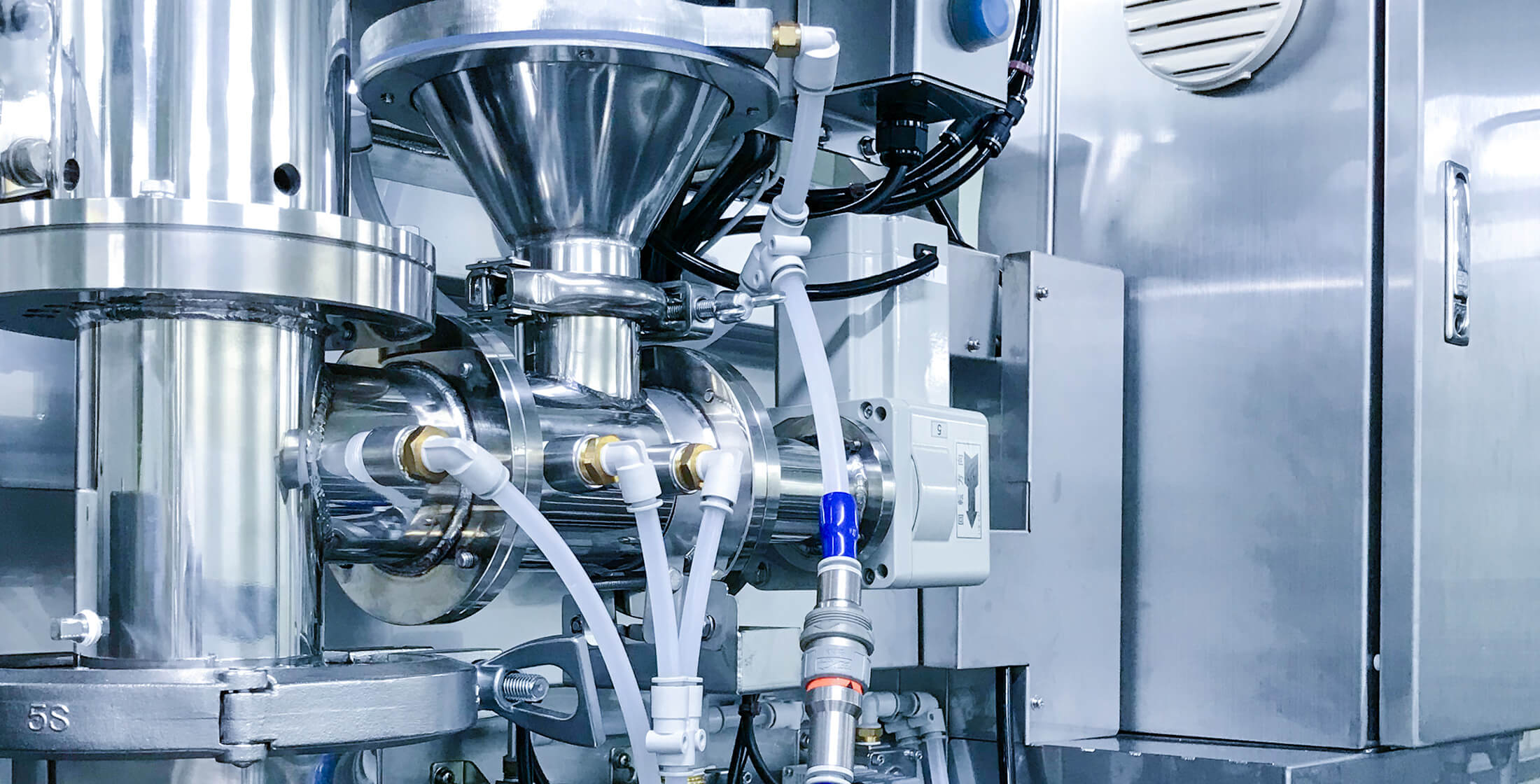

Rice delivery process

Rice delivery process

Foreign materials such as bran balls and broken rice are removed by placing rice in a wide hopper that can be placed on the floor without the need for a pit, and passing it through a flow-through sorting machine.

The standard capacity of the rice storage tank is 2 tons, and the number of tanks can be installed as needed.

In addition, air conveyance ensures the rice is transferred to the rice milling machine without damaging the rice.

No residual rice is retained, which reduces time loss during lot changeover and improves maintainability.

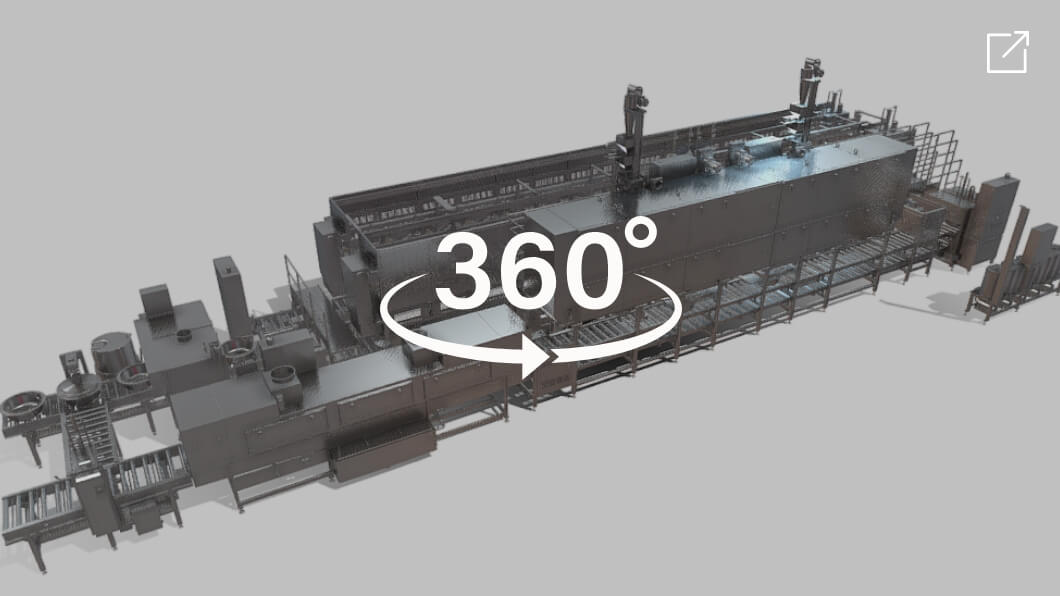

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

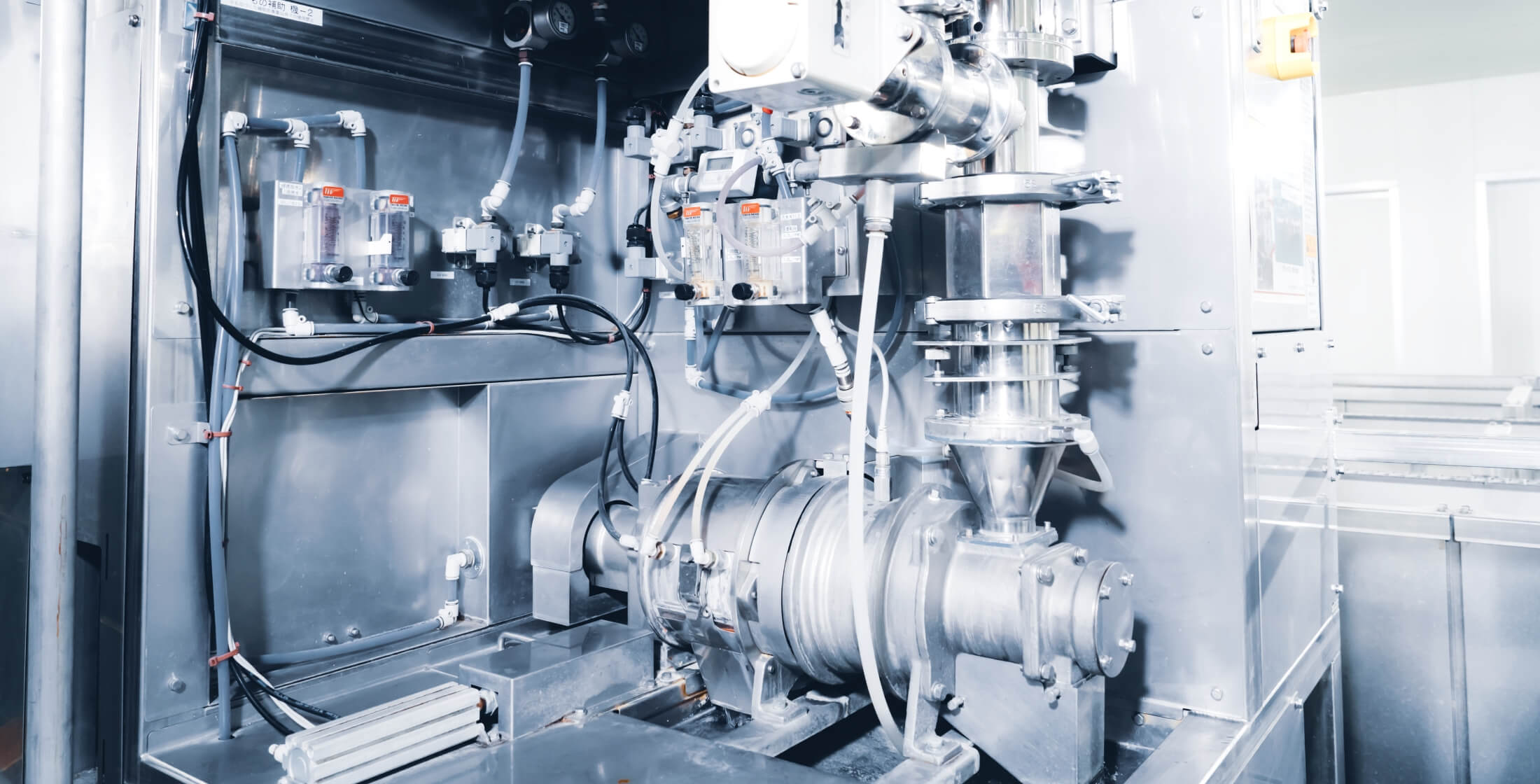

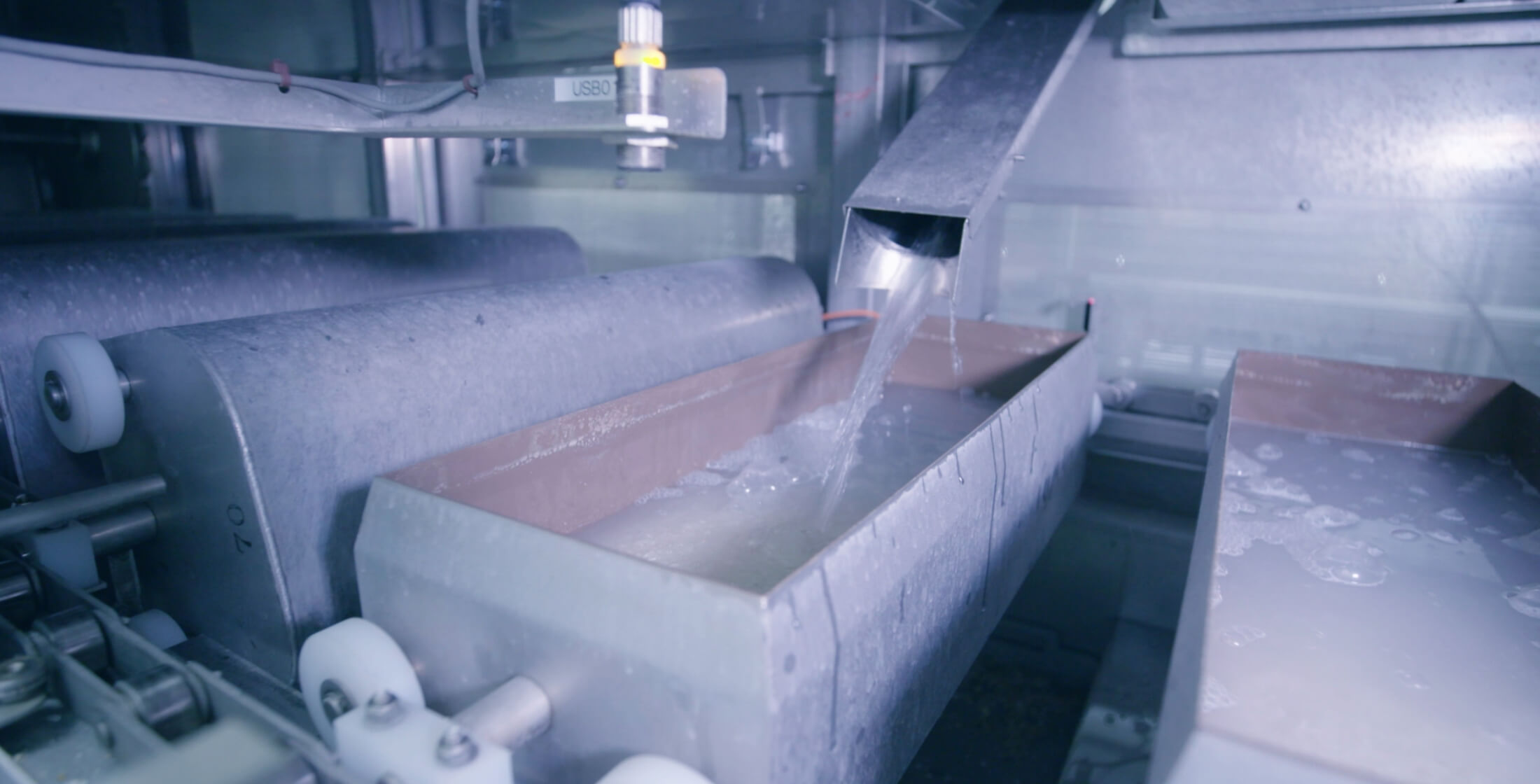

Rice washing process

Rice washing process

The rice washing machine can save a large amount of water compared to the conventional model by the unique technology of SATAKE. Rice is washed efficiently and quickly at a constant water temperature. The yield of the dehydrator is as high as 98.7%*4, which prevents the occurrence of broken rice after soaking.

*4 Based on our research

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

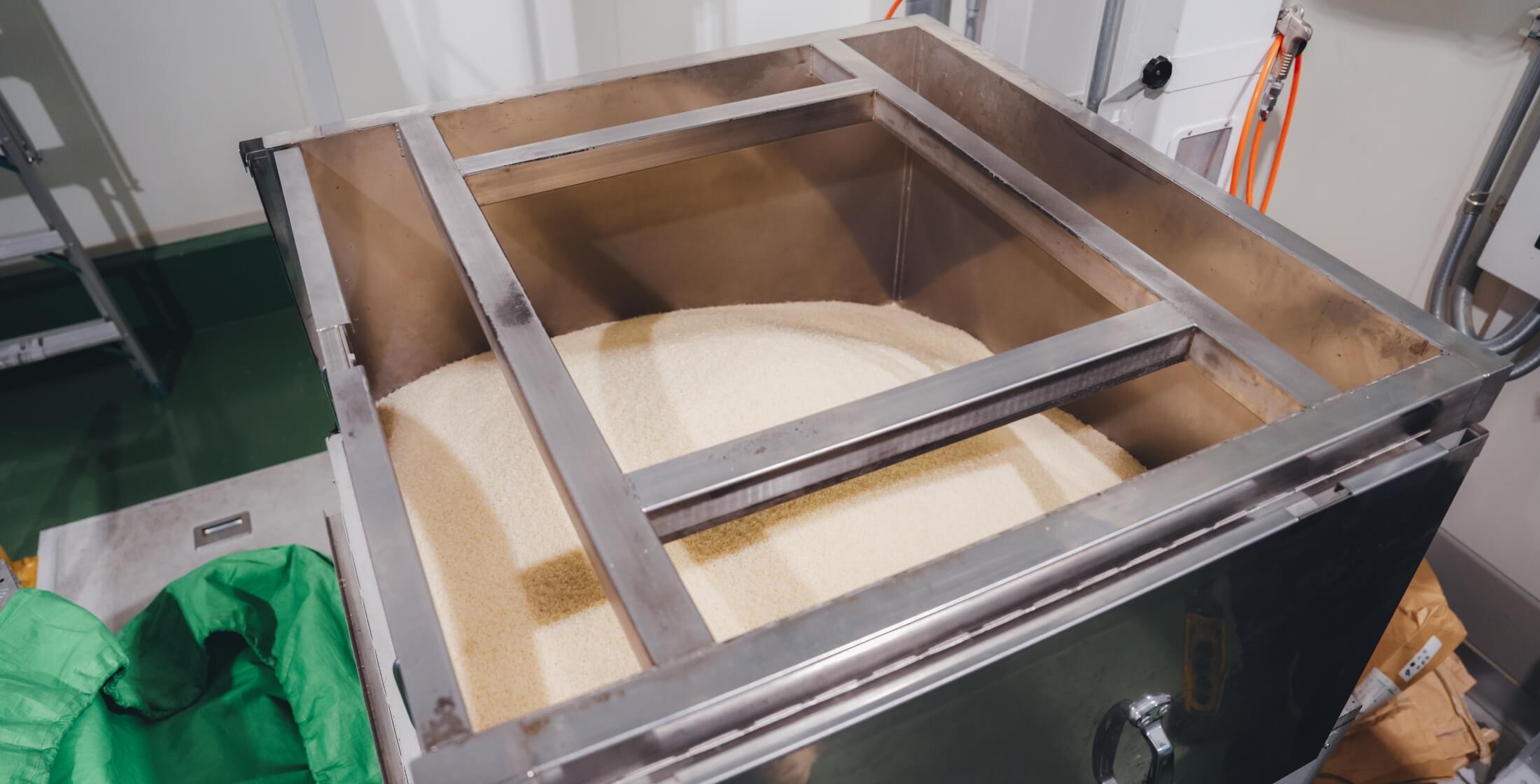

Soaking process

Soaking process

Special containers are used for soaking. Compared to soaking in a cooker, the space is saved by approximately 40%*5, making effective use of space. After soaking is completed, water is cut by reversing the packs and put into the rice cooker to supply cooking water.

*5 Based on our own research, compared to our company's product

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

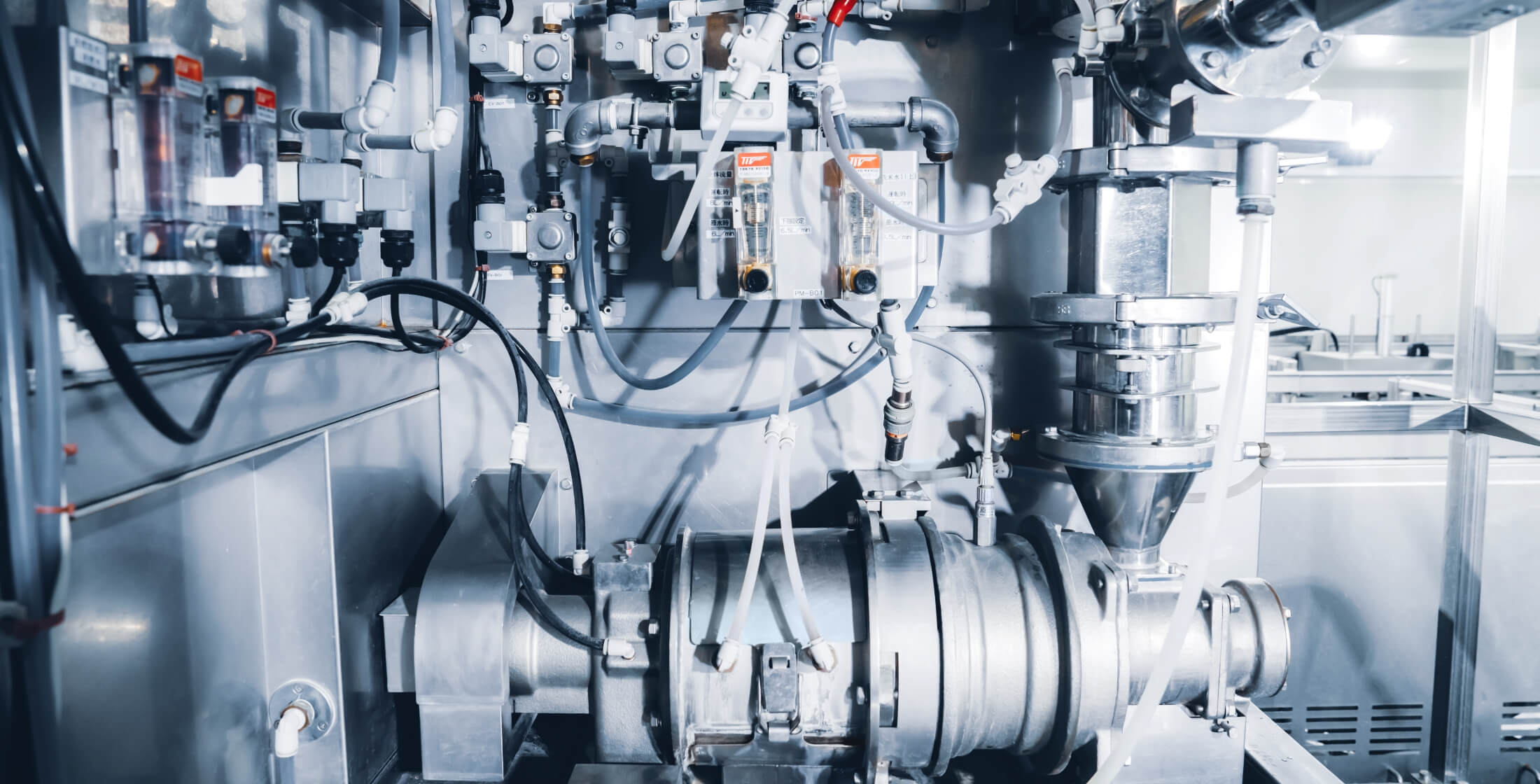

Seasoning process

Seasoning process

The "seasoning tank unit", which seasonings are added, is a weighing method that supports up to five types as standard. Seasoning is pumped to the seasoning supply unit and supplied to the cooker by "subtractive load cell weighing". Stir and knead the seasonings with two stirring paddles. The round cooker shape reduces uneven stirring.

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

Rice cooking process

Rice cooking process

"The 'Pressurized' single-pot cooking method allows for individual rice cooker operation, making it flexible for small batches and multiple varieties. By cooking at a high pressure of 1.2 atmospheres and 106°C, it produces evenly cooked, glossy, and firm 'fluffy rice.'

Pressurization provides more intense heat, which prevents deterioration of eating quality and maintains good taste longer.

Also, the lid and cooker are chucked in four places when cooking rice. The inside of the cooker is maintained at a high and even temperature to reduce variations in quality. In addition steam is exhausted centrally through piping. A dry and clean environment is always maintained.

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

Steaming process

Steaming process

When the rice is cooked up, rice is transfered to the lower level, and then for the 25 minutes steaming process. The inside of the steaming unit is automatically controlled to around 60 °C with electric warm air.

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

Inversion process

Inversion process

Loosen the cooked rice to remove excess water. The direction of rotation and conveyor speed of the smoothing blade are controlled automatically and can be changed. After inverting, weigh the tray and then pile it up.

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.

Cleaning process

Cleaning process

Clean the rice cooker and lid with return water* after cooking. It can be cleaned with a high-pressure pump without residue. After that, the cleaning is completed after rinsing with fresh water and blowering.

*Water used in the primary cleaning is reused in the secondary cleaning. Cleaning with fresh water for finishing reduces water drainage.

3D View

See a 3D view of the entire line*Move to the external 3D viewer "Sketchfab".

*Loading may take some time,

so We recommend accessing via fiber optic line or Wi-Fi environment.