SILK Lineup/Product specifications Lineup of facility according to size

We propose a variety of line configurations to match the amount of rice cooked by the customer. SATAKE offers a lineup of 60, 80, and 120 cookers. We can handle even smaller and larger facility sizes, so please contact us.

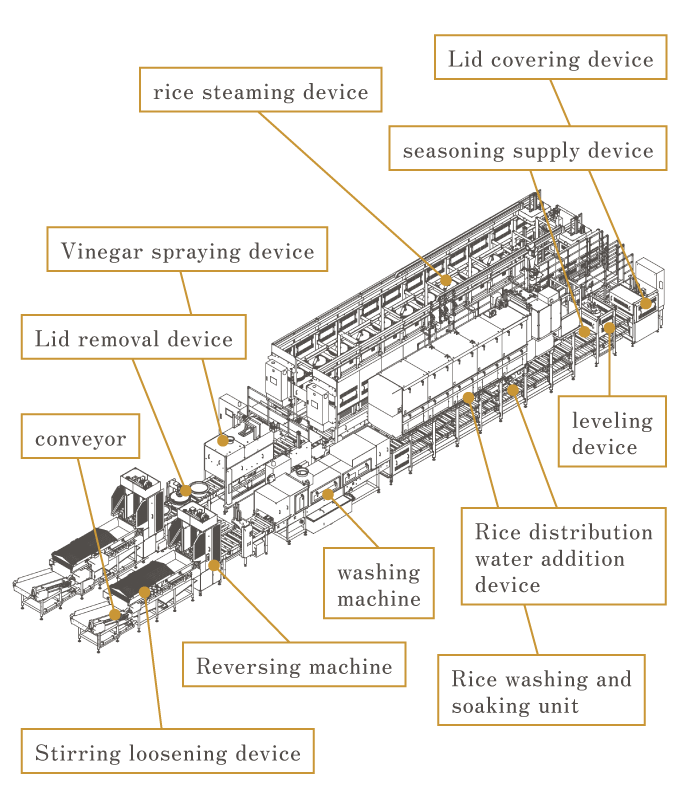

60cookers

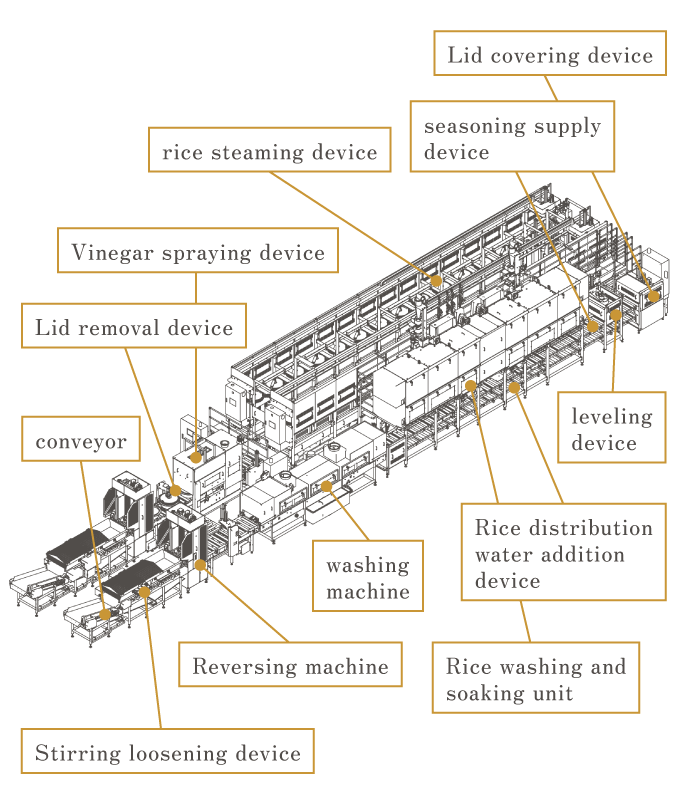

80cookers

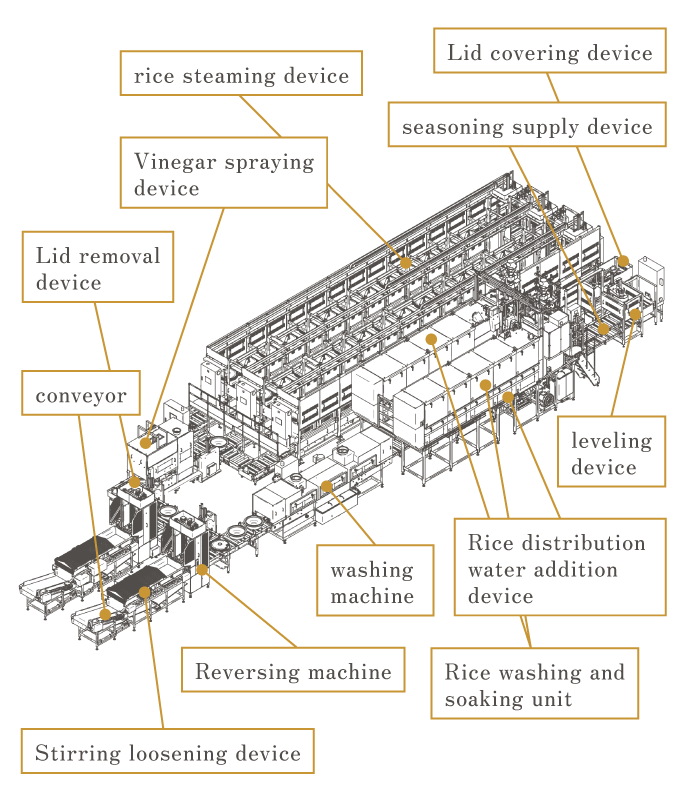

120cookers

In case of 60cookers/h

Process

- Receiving Raw Materials

- Raw materials are transported using air conveyance from the nanometer equipment.

- Rice washing

- Washing rice using rice polishing technology

- Soaking

- Soak in a special container for 70 minutes

- Add seasoning

- Pour in a fixed amount by weighing

- Leveling

- Smooth the surface so that it is level

- Cooking rice

- Cook rice for 20 minutes at 1.2 atmospheres and 106℃.

- Steaming

- Steam for 25 minutes at a constant temperature.

- Vinegar spraying

- Spray vinegar by weighing

- Inversion loosening/lid pot cleaning

- After inverting, loosen and wash the lid pot one by one.

We will propose the most suitable equipment according to the customer's rice cooking amount and factory size. For more information, please contact us using the web form.

In case of 80cookers/h

Process

- Receiving Raw Materials

- Raw materials are transported using air conveyance from the nanometer equipment.

- Rice washing

- Washing rice using rice polishing technology

- Soaking

- Soak in a special container for 70 minutes

- Add seasoning

- Pour in a fixed amount by weighing

- Leveling

- Smooth the surface so that it is level

- Cooking rice

- Cook rice for 20 minutes at 1.2 atmospheres and 106℃.

- Steaming

- Steam for 25 minutes at a constant temperature.

- Vinegar spraying

- Spray vinegar by weighing

- Inversion loosening/lid pot cleaning

- After inverting, loosen and wash the lid pot one by one.

We will propose the most suitable equipment according to the customer's rice cooking amount and factory size. For more information, please contact us using the web form.

In case of 120cookers/h

Process

- Receiving Raw Materials

- Raw materials are transported using air conveyance from the nanometer equipment.

- Rice washing

- Washing rice using rice polishing technology

- Soaking

- Soak in a special container for 70 minutes

- Add seasoning

- Pour in a fixed amount by weighing

- Leveling

- Smooth the surface so that it is level

- Cooking rice

- Cook rice for 20 minutes at 1.2 atmospheres and 106℃.

- Steaming

- Steam for 25 minutes at a constant temperature.

- Vinegar spraying

- Spray vinegar by weighing

- Inversion loosening/lid pot cleaning

- After inverting, loosen and wash the lid pot one by one.

We will propose the most suitable equipment according to the customer's rice cooking amount and factory size. For more information, please contact us using the web form.