Product Overview What is Pressurized IH Rice Cooking facility?

Rice cooking facility that

produces "Firmness" and "Gloss"

Satake's know-how on rice, from rice washing to cooker washing, is concentrated.

We have built a line that maintains the original taste of rice with "Firmness" and "Gloss."

Advantages of Introduction of SILK

Improvement of taste and quality stability

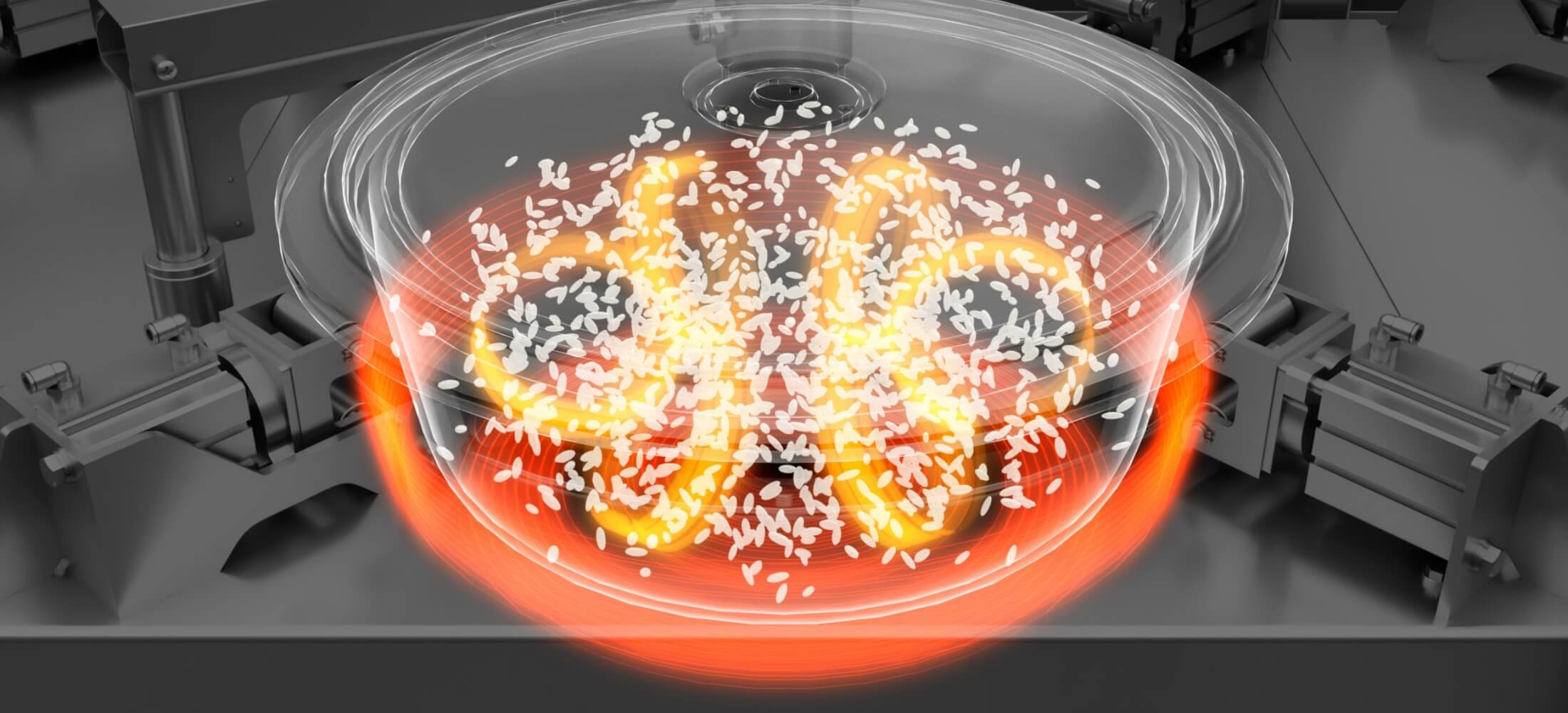

heats rice at 1.2 atm x 106°C at once.

By heating the bottom and sides of the cooker itself, the whole cooker is heated evenly at once to cook rice. In addition, by applying pressure inside the cooker, heat is transmitted to the rice core, bringing out even more delicious flavor.

Heat to the core at higher temperature

Pressurize inside the cooker to 1.2 atm and cook rice at 106°C. Heat is transmitted to the rice core, cooking it to a firm, grainy, fluffy and shiny rice.

Gelatinize the rice in the cooker evenly.

Effective heating control from both sides of the bottom and sides of the cooker promotes convection in the cooker. This ensures even cooking and reduces unevenness in the cooking process.

Long-lasting deliciousness

High-pressure, high-temperature rice cooking allows the rice inside the cooker to gelatinize evenly, resulting in little deterioration in taste and maintaining good taste over time.

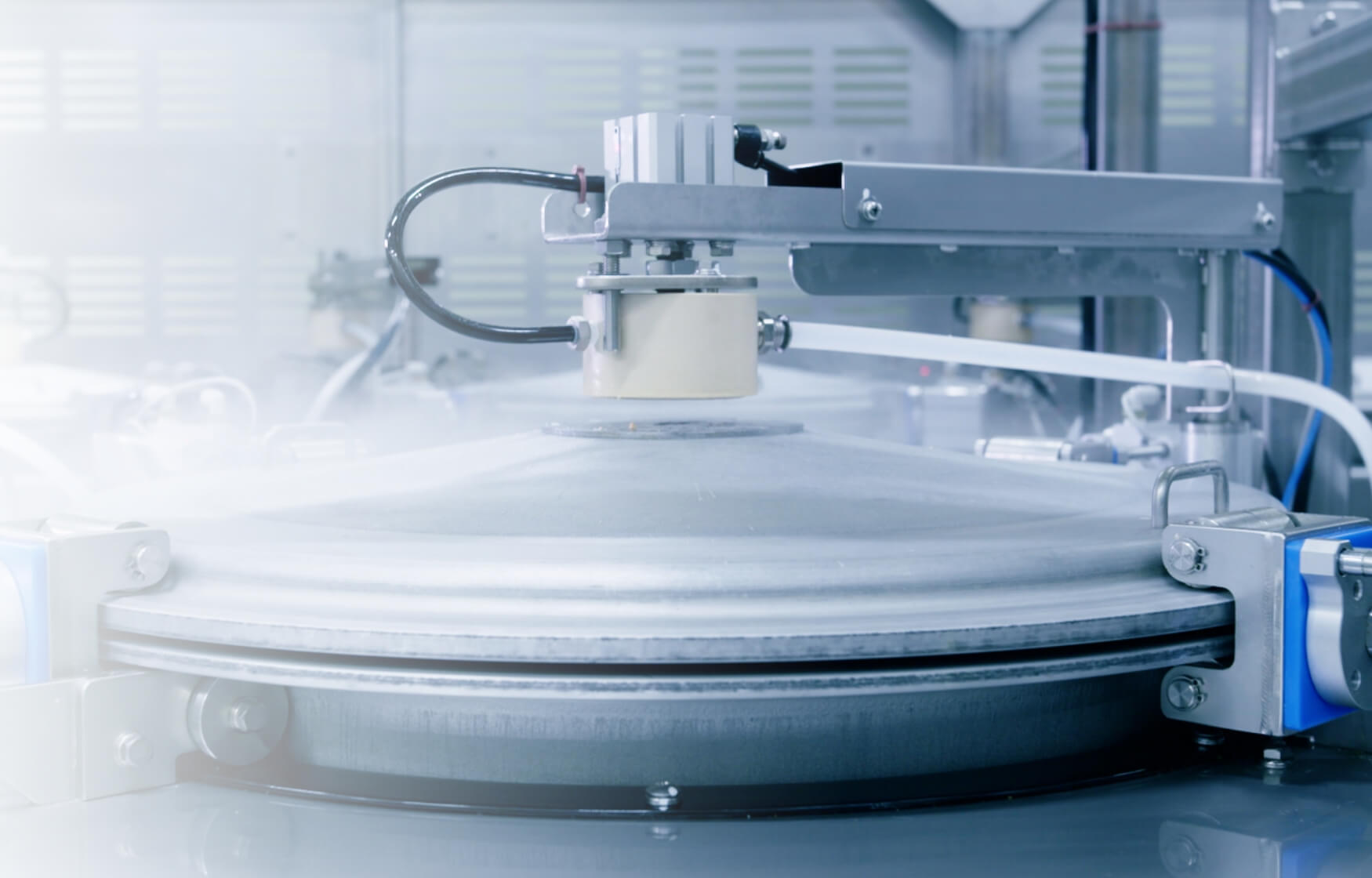

Mechanism to keep steam from escaping

The dry environment is maintained by preventing steam generated during rice cooking from escaping due to central exhaust.

Collection and management of "temperature," "time," and "weight" data for all processes.

Satake's unique manufacturing control system allows to collect various types of data from all processes in the production line and manage them as Excel data. This makes stable operation and quality control easy.

Main data collection

Weight control*1

- Rice weight

- Added water weight

- Seasoning weight

- Cooked rice weight

- Sprayed vinegar weight

Time management*2

- Soaking time

- Rice transfer time

- Seasoning time

- Cooking time

- Vinegar spraying time

Temperature control*3

- Washing water temp.

- Soaking water temp.

- Cooking water temp.

- etc.

*1 Data management for the amount automatically put into each cooker

*2 Data management of the elapsed time for each container

*3 Data management of the temperature in the cooker

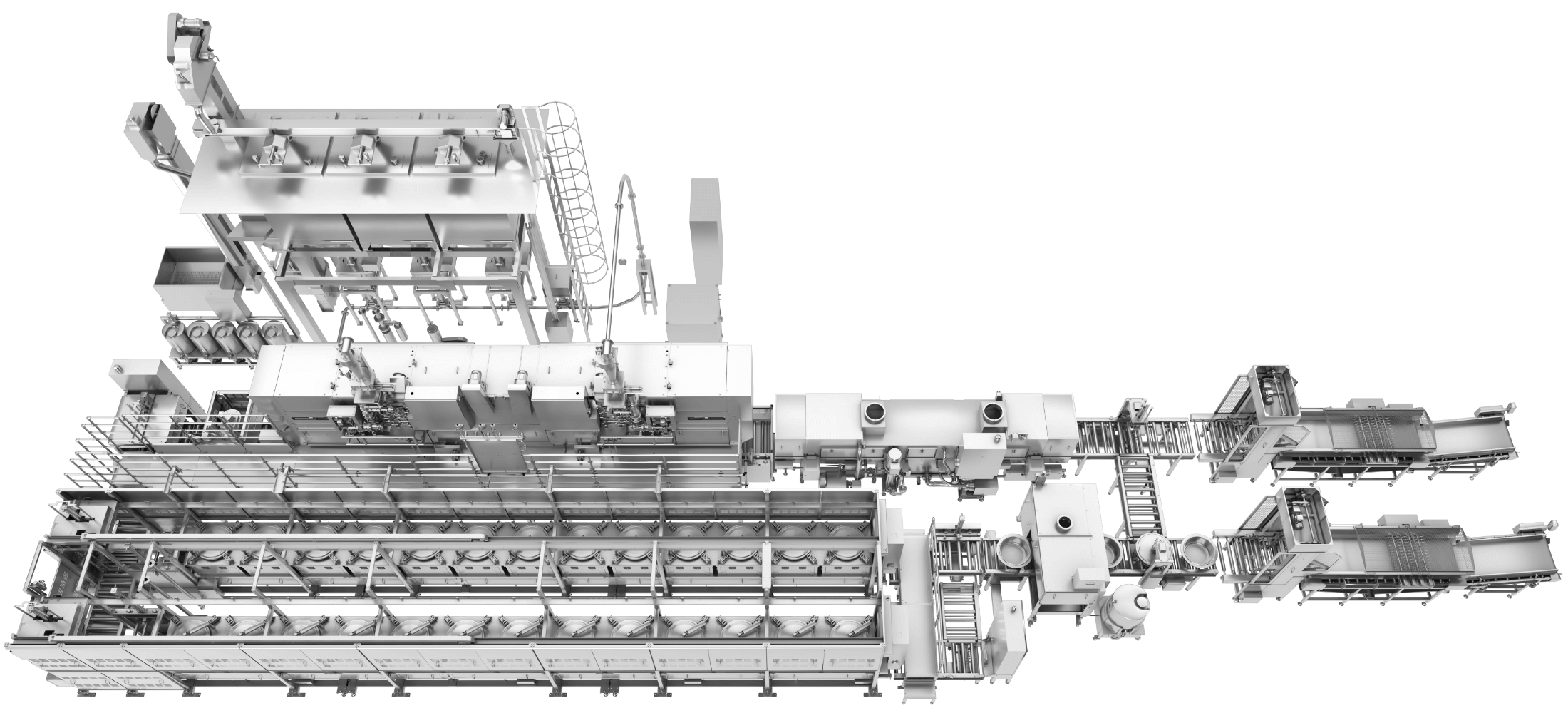

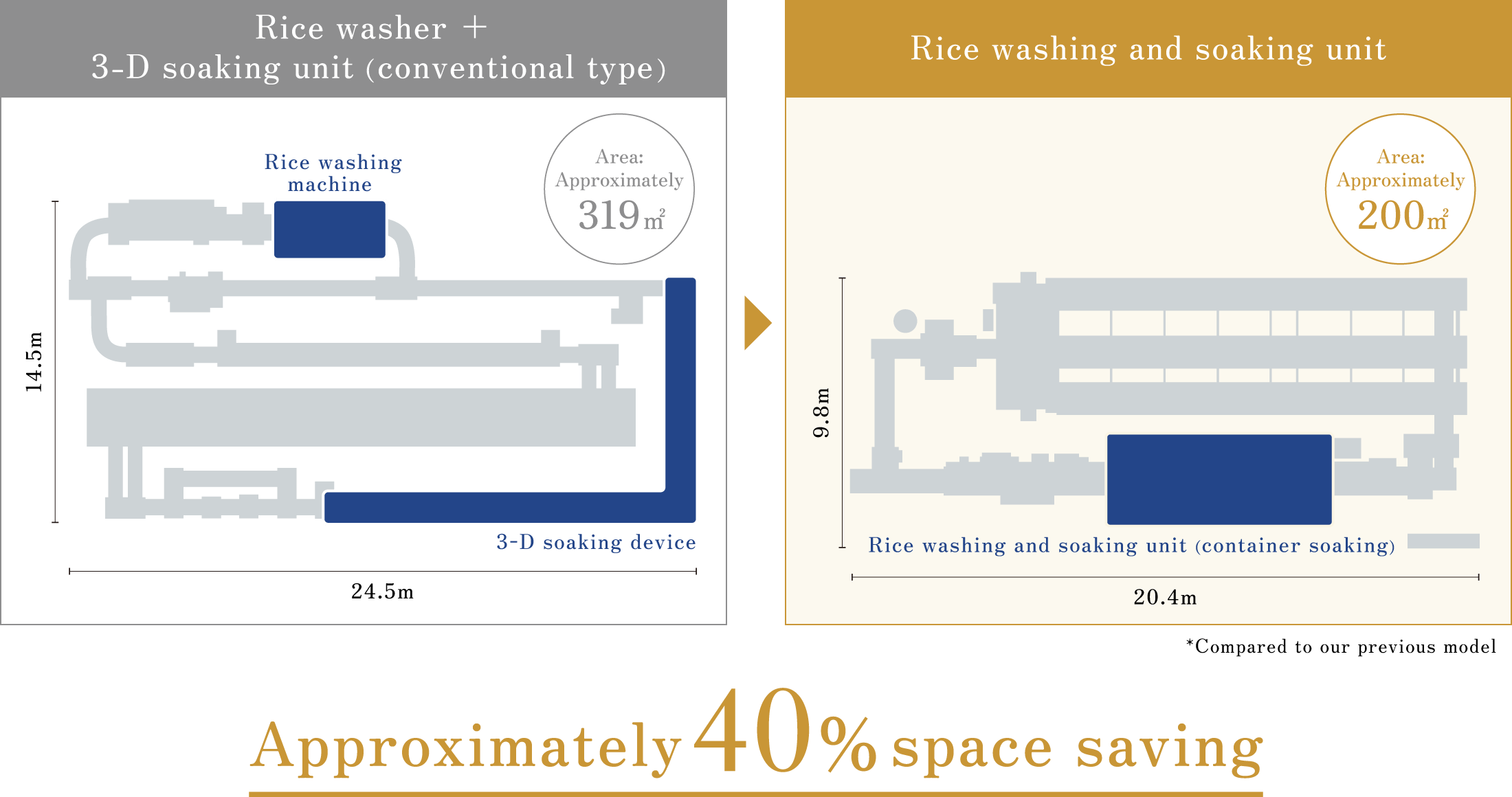

Realization of space-saving

Satake's original manufacturing method (container soaking method) enables compact design and layout. Space savings of approximately 25% to 40% can be achieved.

Unified design from washed rice to soaking

Usually, the rice washing machine and the soaking unit are separated from each other, requiring a lot of space, but Satake's SILK rice cooking line integrates them as a "rice washing and soaking unit", which saves space.

Comparison of 120 pots/h line

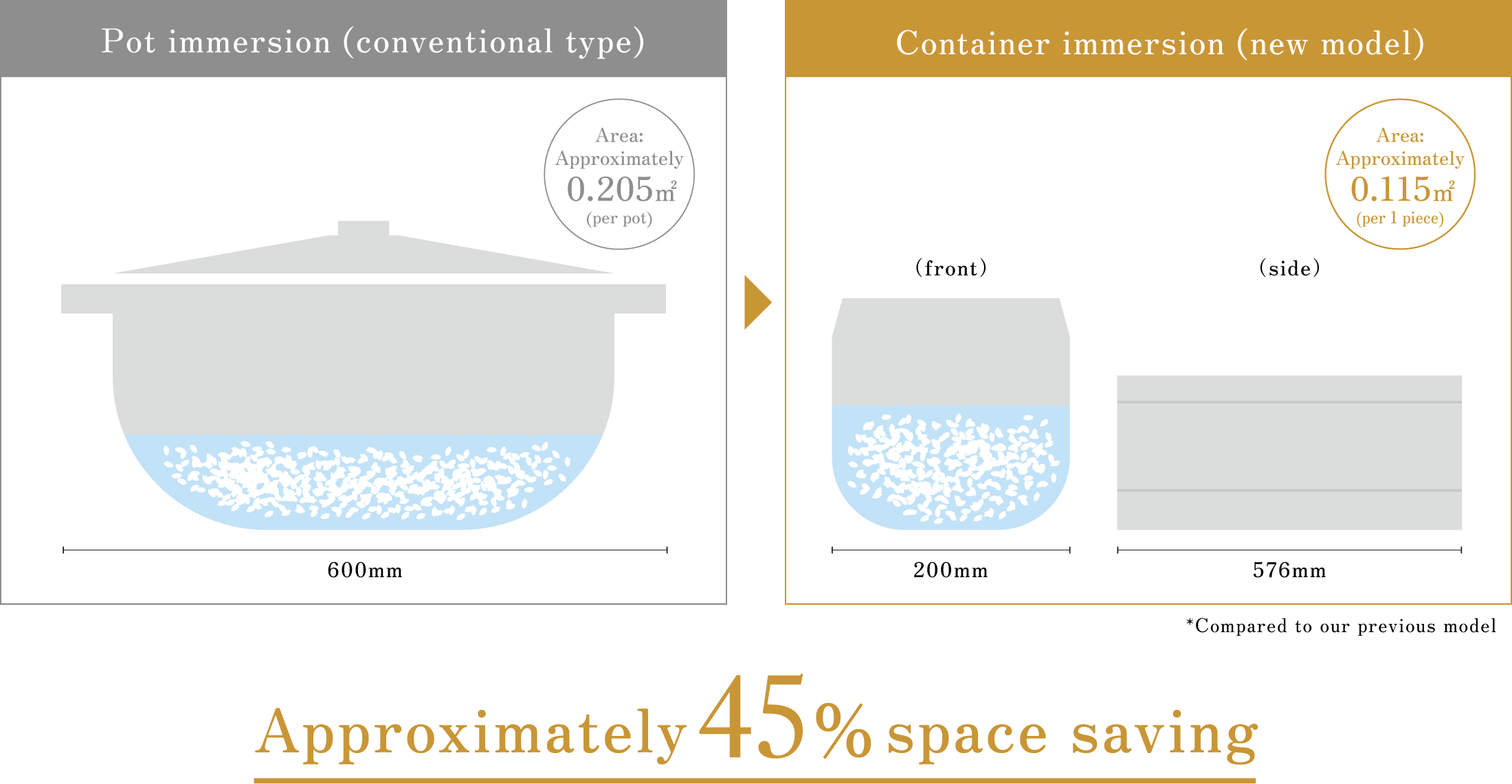

Saving space by soaking with containers

Instead of soaking in a conventional rice cooker, soaking is done in Satake's unique containers, allowing for an efficient layout in a limited space. Initial costs can also be reduced by space saving.

Example of comparison per pot

Rice cooking facility that is

friendly to people and the environment

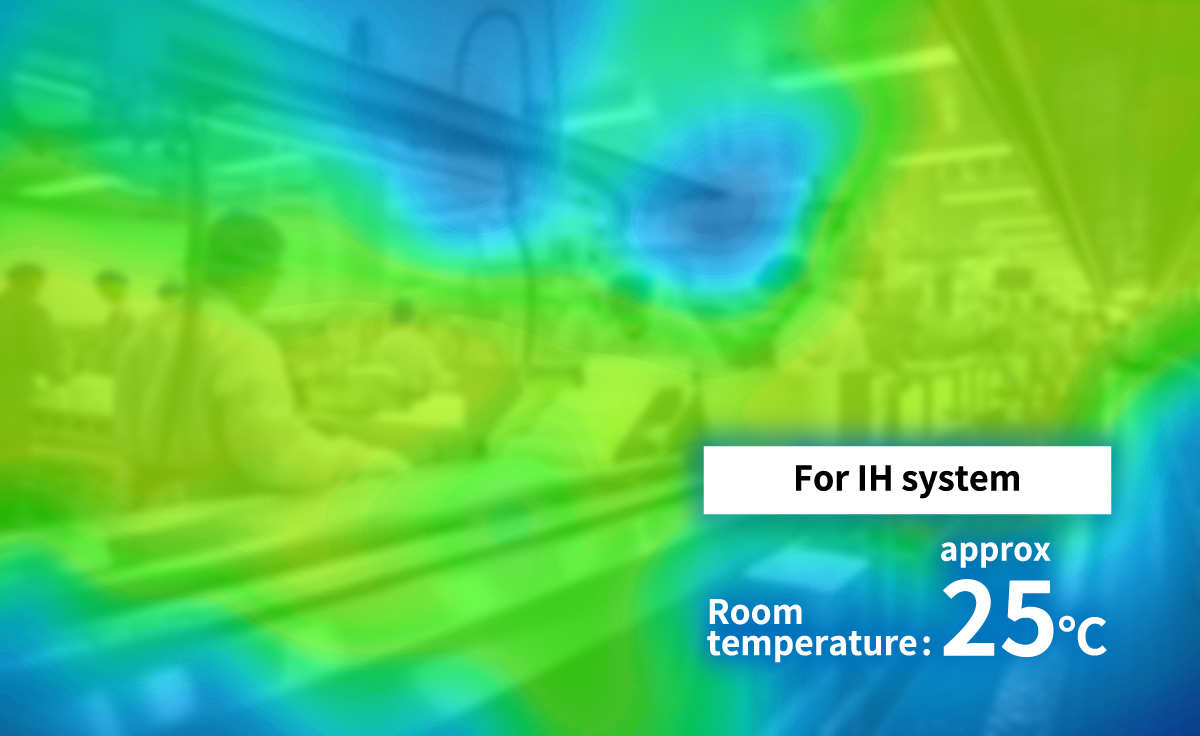

SILK's pressurized IH rice cooking facility produces less waste heat than conventional gas rice cooking, creating a safe and comfortable working environment. It also contributes to reducing the running cost of air conditioning equipment in the cooking room.

People-friendly and comfortable work environment

Compared to conventional gas rice-cooking facility, IH rice-cooking facility can significantly reduce the amount of waste heat during rice cooking and enable stable control of the room temperature in the facility. This provides a comfortable working environment for people working on site. Prevention of burning and spillage during rice cooking reduces cleaning burdens and improves maintenance, and from an environmental standpoint, reduces waste loss.

Environmentally friendly facility design

Compared to gas rice cooking facilities, the amount of exhaust heat can be reduced. In addition, the use of a water-saving rice washer based on Satake's proprietary technology significantly reduces water consumption and wastewater, resulting in an environmentally friendly facility design.

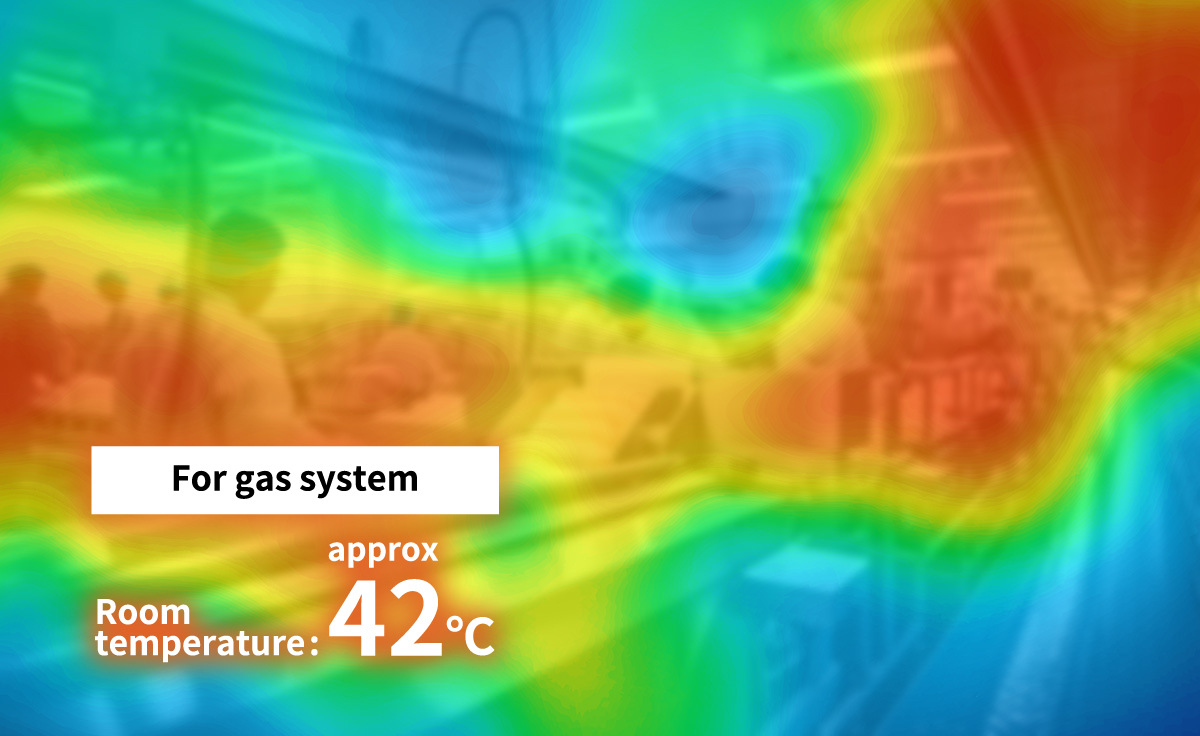

Room temperature comparison image of rice cooking line

Conventional gas rice-cooking facilities require the installation of an exhaust hood due to high room temperatures of approximately 40°C or higher, but SILK's rice cooking facilities maintain a room temperature of approximately 25°C and do not require the installation of an exhaust hood. In addition, the required ventilation frequency is reduced to about half of the conventional systems, which also reduces the running cost of air conditioning system.

*Image is for illustration purposes.